Quick Links ...

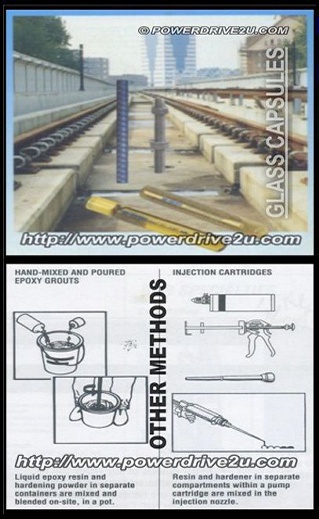

1... Applications are, steel structure works, highrise building construction,

port & harbour installations, oil refinery & in-plant installations,highway &

raiway projects, water supply & waste treatment projectsand etc.

Rebar dowelling : starter bars in pilecaps, adding new columns & beams,

construct new floor slabs & staircases, thickening columns etc. More Info

2... POWERDRIVE chemical anchors / adhesive anchors is increasingly becoming

a vital component of both new construction and existing structure renovation.

The easiest and fastest way to achieve safe and high strength anchorage.

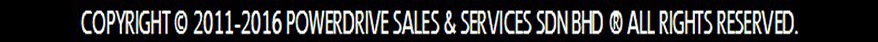

3... All the adhesive components needed for secure bonding are industrial

premeasured and filled in the GLASS CAPSULES. No guesswork or

messy mixing of chemicals (e.g, hand-mixed epoxy grouts and injection

cartridges types) on the job-site. The exact number of glass capsules

required for the job can be predetermined.

4... POWERDRIVE chemical anchors / adhesive anchors are non-expanding,

and therefore do not set up stress zones in the concrete base material.

Stress-free installation makes them ideal for installing at close fixing centres

or near concrete edges. They are capable of withstanding extremely high loads,

are vibration and shock-proof and do not slip or back out the hole under torque

or axial loading.

5... Advantages are, completely sealed anchors hole, economical stainless steel

anchoring, may be used in water-filled holes and even underwater like harbour

loading dock bumpers. High strength even with reduced anchor to anchor and

anchor to edge distances. Can be used in either damp diamond cored or

carbide drilled holes.

port & harbour installations, oil refinery & in-plant installations,highway &

raiway projects, water supply & waste treatment projectsand etc.

Rebar dowelling : starter bars in pilecaps, adding new columns & beams,

construct new floor slabs & staircases, thickening columns etc. More Info

2... POWERDRIVE chemical anchors / adhesive anchors is increasingly becoming

a vital component of both new construction and existing structure renovation.

The easiest and fastest way to achieve safe and high strength anchorage.

3... All the adhesive components needed for secure bonding are industrial

premeasured and filled in the GLASS CAPSULES. No guesswork or

messy mixing of chemicals (e.g, hand-mixed epoxy grouts and injection

cartridges types) on the job-site. The exact number of glass capsules

required for the job can be predetermined.

4... POWERDRIVE chemical anchors / adhesive anchors are non-expanding,

and therefore do not set up stress zones in the concrete base material.

Stress-free installation makes them ideal for installing at close fixing centres

or near concrete edges. They are capable of withstanding extremely high loads,

are vibration and shock-proof and do not slip or back out the hole under torque

or axial loading.

5... Advantages are, completely sealed anchors hole, economical stainless steel

anchoring, may be used in water-filled holes and even underwater like harbour

loading dock bumpers. High strength even with reduced anchor to anchor and

anchor to edge distances. Can be used in either damp diamond cored or

carbide drilled holes.

.jpg)